METSO LOKOTRACK LT330D MOBILE CRUSHING AND SCREENING PLANT

METSO LOKOTRACK LT330D MOBILE CRUSHING AND SCREENING PLANT

Lokotrack® LT330D™ is an all-electric way to combine a crusher and screen on the same chassis. Despite having a high-capacity crusher and screen, LT330D is still easily transportable enabling efficient contract crushing.

Lokotrack® LT330D™ is an all-electric way to combine a crusher and screen on the same chassis. Despite having a high-capacity crusher and screen, LT330D is still easily transportable enabling efficient contract crushing.

BENEFITS

- Two units combined into one

- Remarkable savings in energy, transportation and maintenance costs

- High-capacity ensured by a powerful crusher and a purposely designed, wide dual-slope screen

- Excellent energy efficiency

- Quick to setup with hydraulic functions

MACHINE SPECIFICATIONS

| Crusher | Nordberg® GP330™ / HP300™ |

| Engine | CAT®, 405 kW |

| Feed opening | 230 mm |

| Machine weight | 67 000kg |

Engine

Feed opening

Machine weight

CAT®, 405 kW

230 mm

67 000kg

FEATURES

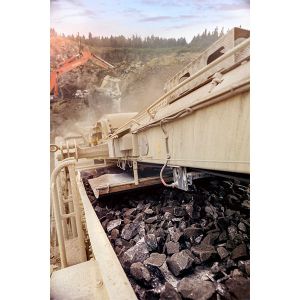

Lokotrack® LT330D™ can be equipped with either Nordberg® GP330™ or HP300™ cone crushers. To achieve maximum performance in all applications, GP330 offers a wide selection of strokes together with a large setting range. HP300 is a proven solution with an installed base of thousands of units around the world. A purposely designed 2 000 mm (6’ 7”) wide dual-slope screen provides excellent total throughput and complements the combination.

During operation, Lokotrack LT330D is fully electrically driven. To achieve the most economical operation, an external power source can be used. In locations where this is not possible, an

integrated CAT® diesel engine and 500 kVA generator power package ensures efficient operation. After arriving on site, the unit is quickly set-up and ready for action thanks to hydraulic cylinders located in the screen and conveyors.

In LT330D, special emphasis has been put on safe maintenance and operation. Extensive platforms and good access make crusher wear part and screen mesh changes quick, easy and safe. Metso IC™ process control system further ensures LT330D operates in a safe and efficient way.

PROCESS OVERVIEW

Lokotrack LT330D is typically used as secondary or tertiary crushing plant in a multi-stage crushing process to produce up to three calibrated end products. In an ideal situation, the LT330D is combined with the Lokotrack LT120E primary jaw crushing plant to produce 1 to 3 calibrated end-products. This two-stage process can be fully electric with external power source or diesel-electric by using on-board diesel generators when there’s no external power source available.

HOW IT WORKS

Primary Lokotrack plant feeds the material to the lifting conveyor of Lokotrack LT330D, which transports the material to the screen. The oversize material is taken to the cone crusher and the screened material is divided to the product conveyors. After the material is crushed, the revolutionary centrifugal lifting conveyor returns it back to the screen in closed circuit.

Power can be supplied either from external network or from 500 kVA onboard diesel generator.