Checking the Spider Bushing on the Sandvik Cones – CH420, CH430 & CH440

What is the spider bushing?

The Spider bushing is located at in the top shell and is responsible for supporting the top of the main shaft.

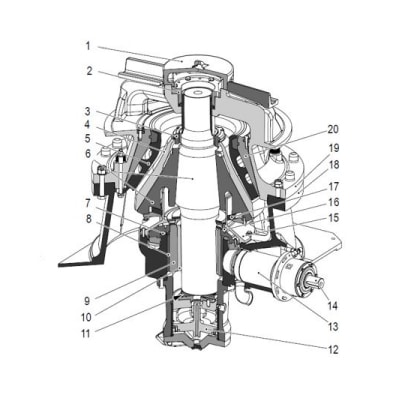

The figure below shows a section view of the crusher and an ISO section of the cone body. The support from the spider bushing and inner eccentric can be observed.

Figure 1 above taken from the CH430 maintenance manual

- Spider cap

- Spider bushing

- Head nut

- Mantle

- Concave ring

- Mainshaft with head centre

- Eccentric wearing plate

- Bottomshell bushing

- Eccentric

- Eccentric bushing

- Step bearing

- Hydroset piston

- Pinionshaft housing

- Pinionshaft

- Dust collar

- Locating bar

- Dust seal ring

- Bottomshell

- Topshell

- Filler ring

Why the spider bushing is important?

The Spider bushing has an hour glass figure and as such it has a very tight clearance. Once the spider bushing no longer supports the main shaft, the bottom of the main shaft exerts a large amount of force on inner eccentric bushing.

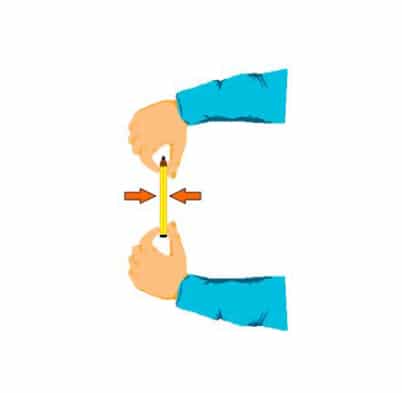

Figure 3 below shows the logic behind the step bushing and the inner eccentric bushing. Imaging holding the bottom of the pencil securely and exerting a force as per the red arrows. This would cause large stress to be exerted at the bottom of the pencil. This is the same logic that applies when the spider bushing is worn.

Figure 4 above show

s the correct grease level (dotted line) in the spider housing taken from Sandvik training files

“S” is the maximum clearance value between the spider bushing and main shaft sleeve at the fulcrum point.

“L” is the distance at which the “S” clearance must be measured to obtain the fulcrum point.

Table 1:

CH420 S=1.6mm L=75mm

CH430 S=1.9mm L=103mm

CH440 S=2.1mm L=165mm

Figure 5 above shows the “L” and “S” measurements taken from Sandvik training files

Figure 6 above shows the use of a feeler gauge to measure spider bushing clearance

How often should it be measured?

Every 250 hours and every liner change

Notes:

Always refer to the Sandvik cone manuals specific to your machine for detailed maintenance guidelines