Maintaining Correct V-Belt Tensioning on Rubble Master Crushers

Importance of maintaining the correct v-belt tensioning:

Too high a v-belt tension will overload the generator bearings and cause a major generator failure which will be costly to repair.

Too low a v-belt tension can allow v-belt slippage which will damage the v-belt as well as the pulleys resulting in avoidable downtime.

How to correctly test belt tension?

Tools required

- Tension meter Otikrik 0-1500 N.m (Part number :212024)

- This can be ordered from our PartsLink department at Pilot Crushtec International. If you want to find out more information on this part, please enquire here

Open the compartment door on Rubble Master machine;

Figure 1 above shows the compartment that needs to be opened

2. Isolate the machine (isolator key removed and battery disconnected)

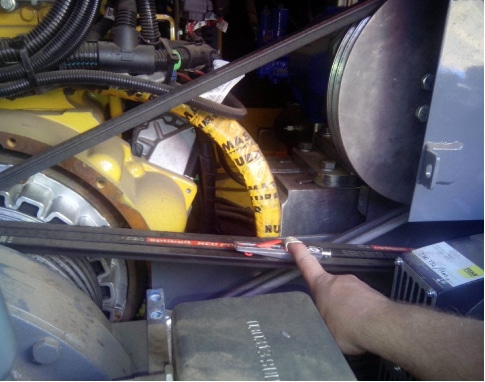

3. Remove generator V-belt cover

Figure 2 shows the generator v-belt guard that must be removed

4. Set the tension meter to 1500 N.m

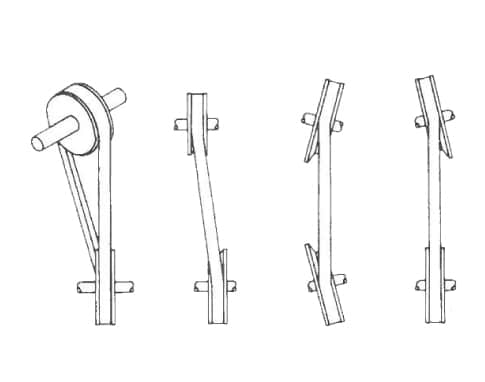

5. Slide the tension meter onto finger then place it on the centre span of the V-belt between the two pulleys

Figure 3 shows the tension meter set to 1500N.m on the v-belt

6. Press your finger down until the tension meter ‘clicks’

7. Remove the tension meter carefully and read the value on the meter

Figure 4 shows the tension meter at the ‘click point’

8. The tension required on the generator V-belts is as follows:

Maximum value 960 N.m

Minimum value 500 N.m

Adjust v-belt tension if necessary

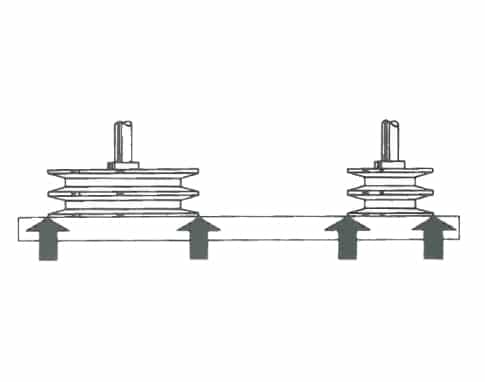

Check pulley alignment

The image above displays the proper alignment which is essential to maintain long belt and pulley life

Figure 5 taken from Fenner Drive Design & Maintenance Manual