Tensioning crawler tracks on mobile machines

In order to ensure that tracks last the life time of your machine, they need to be correctly maintained. Not having the correct track tension can cause the tracks to climb off the sprockets and this is a major job to fit again.

Loose tracks can result in damage to the rollers, idlers or track sprockets which will lead to unnecessary expenses and loss in your production.

Below are a few tips to help ensure this does not happen to your machine.

Checking chain tension

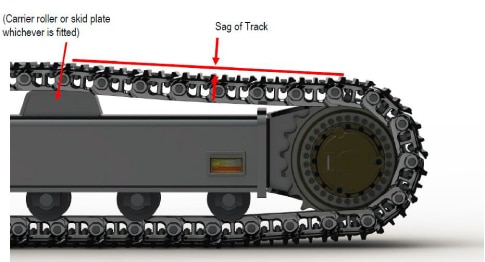

Place a straight edge on top of the track from the drive sprocket roller to the carrier roller(skid plate) and check the droop of the track chain in the centre.If the track slacks more that 15 mm then it must be tensioned.

Figure 1 below shows the crawler track with a straight edge between the drive sprocket and the carrier roller (skid plate)

Tensioning tracks

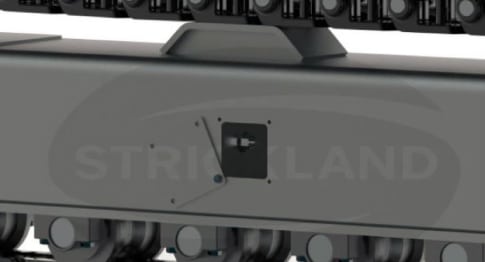

A grease pump with a suitable grease adapter relative to the nipple on the tensioner must be used.

A general purpose EP2 grease may be used to pump tension into the track cylinder.

Pump the track tension cylinder 5 times and then remove grease pump and track machine one length forward and one length back then re-check tension.